PROCESSING EQUIPMENTS

Upgrading

Seed lots require further cleaning treatment to remove adulterants that are similar to pure seed in size and shape, to be separated by air screen cleaner. Removal of seeds larger or smaller than required size (sizing) and removal of cracked, damaged or otherwise defective seeds (grading) is accomplished in this final stage of processing.

Specific gravity separation

This method makes use of a combination of weight and surface characteristics of the seed to be separated. The principle of floatation is employed here. A mixture of seeds is fed onto the lower end of a sloping perforated table. Air is forced up through the porous deck surface and the bed of seeds by a fan, which stratifies the seeds in layers according to density with the lightest seeds and particles of inert matter at the top and the heaviest at the bottom. An oscillating movement of the table causes the seeds to move at different rates across the deck. The lightest seeds float down under gravity and are discharged at the lower end, while the heaviest ones are kicked up the slope by contact with the oscillating deck and are discharged at the upper end. This machine separates seeds of the same density but of different size and seeds of the same size but of different densities.

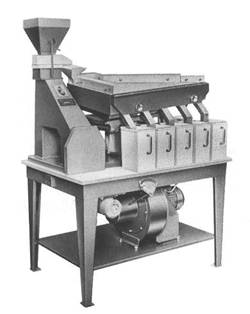

Specific gravity separator

|